One of a kind

Process

One of a kind results.

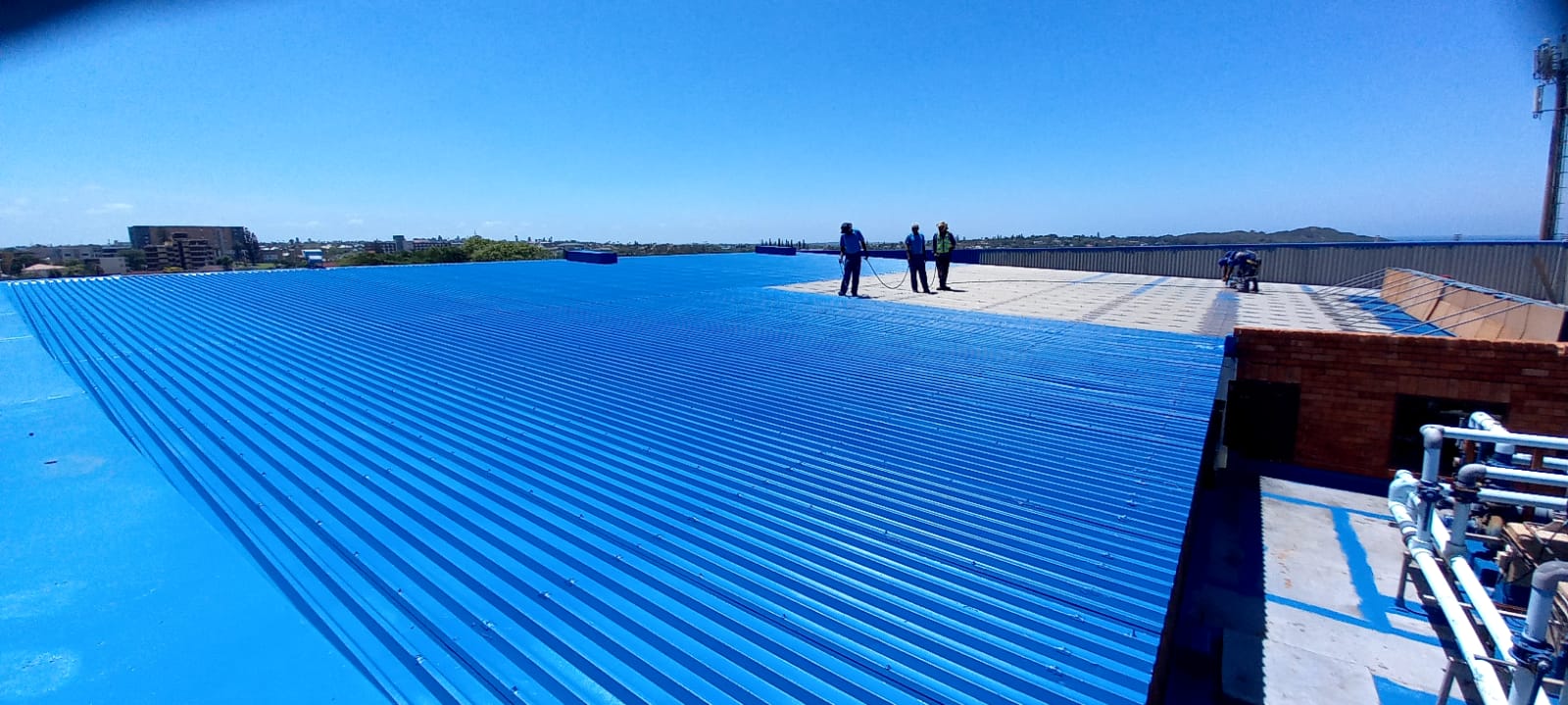

Our Dual-Phase Application Process revolutionises waterproofing by ensuring optimal results and unmatched durability.

This unique process involves two carefully orchestrated phases that work in tandem to create a seamless and fail-safe application.

One of a kind

Process

One of a kind results.

Meet our revolutionary Dual-Phase Application Process

Our

Dual-Phase

Process

Phase 1

Step 1

Roof Inspection And Hazard Mitigation

Our experienced technicians meticulously assess the roof's condition, looking for signs of damage, structural weaknesses, or any other potential risks. With our keen eye for detail, we mitigate these hazards, ensuring a safe and secure roofing system.

Phase 1

Step 2

Cleaning The Roof Surface By Hand

When it comes to cleaning the roof, we go beyond conventional methods by employing a thorough and hands-on approach. Our skilled technicians meticulously clean the roof by hand, ensuring the removal of dirt, debris, and contaminants that can compromise the integrity of the waterproofing application.

Phase 1

Step 3

Treating Problem Areas

We employ specialised techniques and high-quality materials to address these problem areas, ensuring they are repaired and reinforced before the waterproofing application.

Phase 2

Step 4

Apply a Primer Coat

We utilise state-of-the-art airless spray pumps to apply RCM All Purpose Coating with precision and efficiency. Following our prescribed guidelines, we ensure a consistent coverage rate of 4m2 per litre, guaranteeing optimal adhesion and maximum performance. This meticulous application technique ensures that every centimetre of the roof surface is coated with RCM All Purpose Coating, creating a strong and durable foundation for the subsequent waterproofing layers.

Phase 2

Step 5

Provide 6 Hours For Suitable Curing

Allowing suitable curing time is a critical component to ensure the effectiveness and durability of our waterproofing solution. After the application of our advanced coating.

Phase 2

Step 6

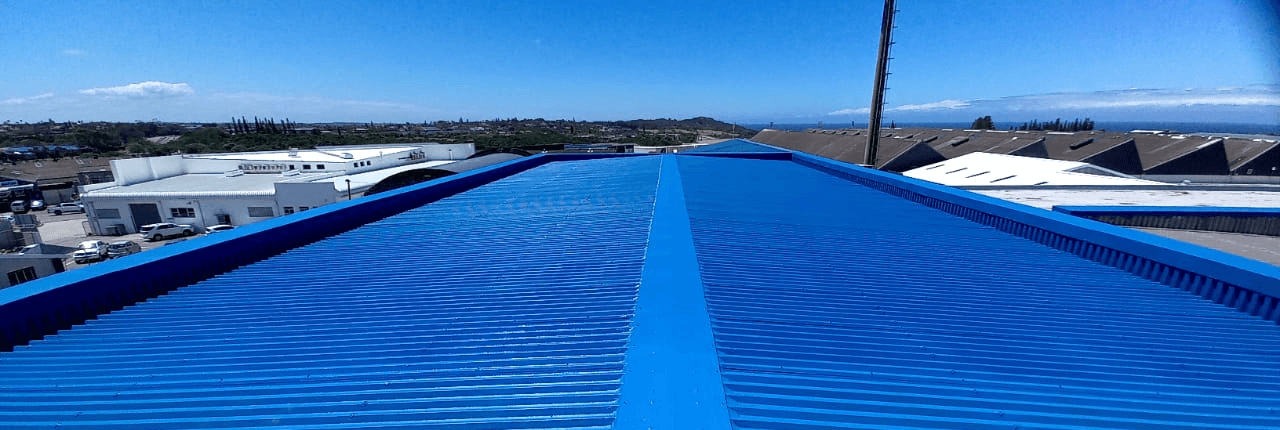

Apply RCM All Purpose Coating

The application of RCM All Purpose Coating membrane plays a vital role in enhancing the durability and insulation properties of your roof. Our skilled technicians utilize cutting-edge airless spray pumps to apply RCM All Purpose Coating with precision and efficiency. Following our prescribed guidelines, we ensure a uniform film thickness of 850 microns, creating a robust and effective barrier against water infiltration and heat transfer

Phase 2

Step 7

Final 24-hour Curation

We strictly adhere to a minimum of 24 hours of curing time, allowing the product to fully bond and form a strong, protective barrier on your roof surface. This patient approach ensures that our waterproofing solution reaches its maximum strength and performance, providing long-lasting protection against water infiltration and environmental elements.

Phase 1

Step 1

Roof Inspection And Hazard Mitigation

Our experienced technicians meticulously assess the roof's condition, looking for signs of damage, structural weaknesses, or any other potential risks. With our keen eye for detail, we mitigate these hazards, ensuring a safe and secure roofing system.

When it comes to cleaning the roof, we go beyond conventional methods by employing a thorough and hands-on approach. Our skilled technicians meticulously clean the roof by hand, ensuring the removal of dirt, debris, and contaminants that can compromise the integrity of the waterproofing application.

Phase 1

Step 2

Cleaning The Roof Surface By Hand

Phase 1

Step 3

Treating Problem Areas

We employ specialised techniques and high-quality materials to address these problem areas, ensuring they are repaired and reinforced before the waterproofing application.

We utilise state-of-the-art airless spray pumps to apply RCM All Purpose Coating with precision and efficiency. Following our prescribed guidelines, we ensure a consistent coverage rate of 4m2 per litre, guaranteeing optimal adhesion and maximum performance. This meticulous application technique ensures that every centimetre of the roof surface is coated with RCM All Purpose Coating, creating a strong and durable foundation for the subsequent waterproofing layers.

Phase 2

Step 4

Apply a Primer Coat

Phase 2

Step 5

Provide 6 Hours For Suitable Curing

Allowing suitable curing time is a critical component to ensure the effectiveness and durability of our waterproofing solution. After the application of our advanced coating.

The application of Eco Insulate membrane plays a vital role in enhancing the durability and insulation properties of your roof. Our skilled technicians utilize cutting-edge airless spray pumps to apply Eco Insulate with precision and efficiency. Following our prescribed guidelines, we ensure a uniform film thickness of 850 microns, creating a robust and effective barrier against water infiltration and heat transfer

Phase 2

Step 6

Apply RCM All Purpose Coating

Phase 2

Step 7

Final 24-hour Curation

We strictly adhere to a minimum of 24 hours of curing time, allowing the product to fully bond and form a strong, protective barrier on your roof surface. This patient approach ensures that our waterproofing solution reaches its maximum strength and performance, providing long-lasting protection against water infiltration and environmental elements.

Success-prone Ingredients

Success-prone Ingredients

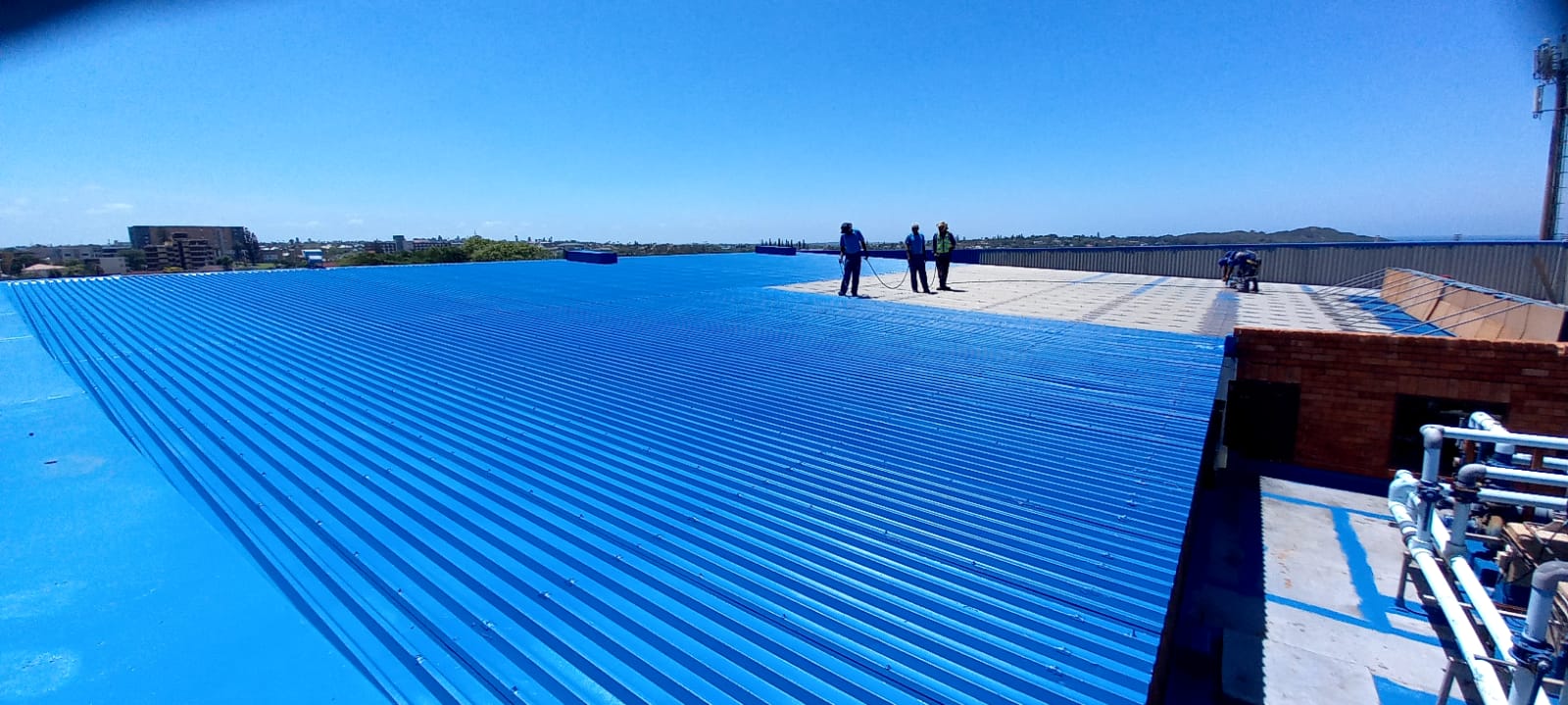

Staff Experience

Our team consists of dedicated professionals who are passionate about their craft and committed to delivering excellence

Supervision

Our experienced supervisors provide guidance, oversight, and support to our skilled technicians, ensuring each project is executed flawlessly

Autonomy

Due to the extensive experience our staff members hold, we can provide near-complete autonomy on projects. This allows us to complete the project without close intervention from the client